Vehicle Service

Whatever the service requirement – make it your business to check the

customer‘s vehicle for TPMS

Establishing if TPMS is present

- Using the TPMS Inspection tool, conduct a search on the vehicle make

and model. - No record signifies that the vehicle either has indirect TPMS or the

vehicle does not have an active TPMS system present. - A listed entry on the diagnostic tool signifies that the vehicle is

equipped with direct TPMS.

TPMS Inspection tool

- REMA TIP TOP recommends the Hamaton H47 or Hamaton H46

(powered by ATEQ) – TPMS/diagnostic tool for detection, inspection,

diagnosis and relearn capability.

The cost-effective H47 – manufactured in partnership with ATEQ – packs

an abundance of features, including integrated OBDII module into a

compact, ergonomic design.

• Provides many simple methods to configure all EU-Pro/T-Pro

generations and program Hybrid 3.5 sensors: create, clone, manually

enter or (from the vehicle‘s ECU) retrieve ID‘s.

• Reads 100% of OE and aftermarket sensors.

• Displays sensor data: ID, tyre pressure, tyre temperature, battery

status and sensor frequency.

• Provides manual, auto and OBDII relearn procedures.

• Built-in OBDII module performs ECU reset in under 2 minutes.

• Ever-increasing vehicle coverage due to frequent database updates.

• User-friendly navigation, multi-language interface and bright colour

display.

• Comes with shock-resistant rubber boot, USB cable, power adapters

(EU, UK and US), quick start guide and carry case.

Sensor malfunction and replacement?

Sensor malfunction and replacement?

A depleted battery is the most common reason for sensor malfunction. On newer cars the lithium ion batteries inside TPMS sensors may last anywhere from five to ten years. A failed sensor battery means the TPMS unit is redundant and no longer providing protection to the driver or passengers.

Recommended advice to the customer

We advise the replacement of all four TPMS sensors at the same time in addition to the spare wheel sensor if no previous maintenance work has been undertaken.

- Replacing all sensors of the same age negates the need to re-visit the dealer and incur additional charges for a secondary service.

- It could avoid the TPMS warning light appearing while on a trip or in traffic.

- It would eliminate the worry of dealing with a failed sensor.

- Illuminated TPMS Malfunction Indicator Lamp (MIL) now results in an immediate MOT failure.

- Replacing all sensors, before or when one fails, helps avoid a last-minute issue while preparing for inspection.

Replacing the sensor to manufacturer‘s specification

Installing the replacement sensor will require tyre removal by a professional tyre fitter. The old sensor should be disposed by the technician and a replacement sensor fitted Correctly according to the manufacturer’s specifications.

Cloning the sensor

You will need to install the new sensor using a diagnostic tool. You simply capture the sensor data and make a CLONE or a COPY like the original. Programmable sensors can be programmed more than once. And it can be programmed whilst in the tyre.

Relearn procedure

If the TPMS sensor is not transmitting a signal, a new sensor will need to be programmed following the car‘s relearn procedure. Relearn procedures can be obtained from www.tiptoptpms.com using your account ID to log in.

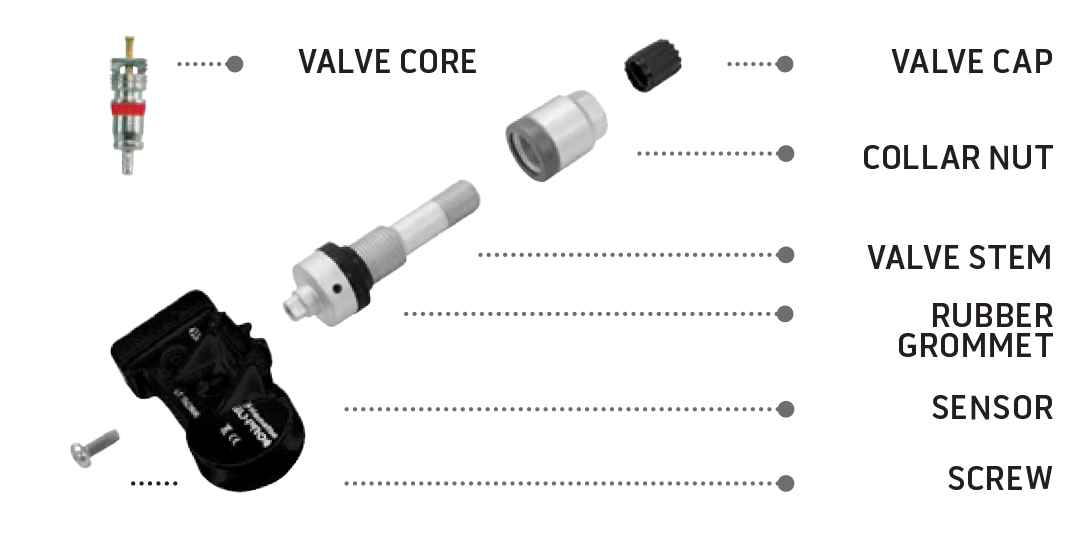

Valve Stem Service

Valve stem components are prone to corrosion and fatigue.

GALVANIC CORROSION, OCCURS WHEN TWO DIFFERENT METALS ARE IN CONTACT IN A CORROSIVE ENVIRONMENT: ONE OF THE METALS EXPERIENCES AN ACCELERATED CORROSION RATE

Best Practice

All OE manufacturers highly recommend, that the TPMS valve is serviced ( alloy ) or replaced ( snap-In ) each time a tyre is removed.

Why service a TPMS valve?

• To prevent valve failure due to corrosion and fatigue.

• To prevent failure due to rubber parts deteriorating.

• To prolong the life of the sensor.

• To create an air tight tyre / rim / valve seal.

• Servicing a TPMS metal valve is slightly different as you

have to replace the serviceable parts…or replace the

valve completely.

Galvanic Corrosion

Galvanic corrosion is the scientific term to describe the usual occurance of corrosion in a TPMS valve assembly.

This phenomenon occurs when two different metals are in contact in a corrosive environment: one of the metals experiences an accelerated corrosion rate.

Here‘s the geeky bit

Galvanic corrosion occurs when the aluminium valve stem reacts with the brass (copper and zinc) valve core in the presence of moisture – due to differences in their electrode

potentials. Electrode potentials relate to the metal‘s capacity of losing

electrons. In the valve situation, aluminium is likely to lose electrons, turning from solid aluminium to an aqueous solution of dissolved aluminium ions. The net result is

corrosion and potentially catastrophic valve failure.

Accentuating the problem

The problem can even be accentuated further as customers or garages retrofit valve caps. The introduction

of an additional cathode in the form of a steel valve cap can cause damage to the aluminium valve stem on the

external thread as well as the inside section.

Saves you money

EU Pro Hybrid Sensors and service kit valve cores are nickel plated to reduce the risk of galvanic corrosion.

Instruction Videos